Powder Coating & Ceramic Coating

What is Powder Coating?

Powder coating is a type of coating that is applied as a free-flowing, dry powder. Unlike conventional liquid paint, which is delivered via an evaporating solvent, powder coating is applied electrostatically and then cured under heat. The powder may be a thermoplastic or a thermoset polymer. It is usually used to create a hard finish that is tougher than conventional paint. Powder coating is mainly used for coating of metals.

ADVANTAGES OF POWDER COATING

- Highly chip and scratch resistant and can resist abuse in cold and hot temperatures.

- Provides a beautiful and uniform quality finish without runs and has excellent chemical, petroleum and salt resistance.

- Allows a thick even coating without traditional wet paint runs and sags.

- Has the ability to encapsulate products, wrap around corners and help eliminate sharp edges.

- Provides premium insulating qualities, both electrical and thermal (inhibits that cold metal feeling)

- Decorative finishes (Hammertone, Antique, Sandtex, Textured, Metallic) applied in one application.

- Excellent ultraviolet light protection (Polyester- Polyurethane) to help reduce colour fading.

- High quality one coat coverage with no primer necessary with virtually unlimited colours in a wide variety of finishes

All prices include abrasive blasting, preparation, and powder coating using a one coat color.

For a second coat, add 50%. Clear coat is required over all metallic and silver coatings.

Cast aluminum and magnesium parts may experience an out-gassing and/or bubbling in the finished powder coat. We will take every precaution to avoid out-gassing, however, we can’t be held responsible for bubbling caused by porous castings.

All prices will be estimates depending on prep time.

Cleaning oils and dirt off parts, masking of all threads or holes or parts is extra. Extra charges for disassembly and assembly and extra prep for powdering.

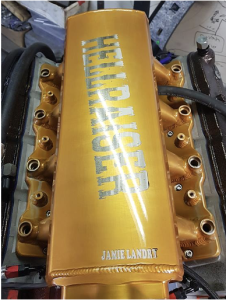

Ceramic coatings

Industry-grade ceramic coating is a chemical polymer solution that is applied to an object to protect it from external paint damage. Typically applied by hand, it creates an additional hydrophobic layer of protection.

Ceramic coatings are considered as ideal coatings on metal which can significantly improve the surface properties of metal materials including anti-fouling, self-cleaning, corrosion resistance, wear resistance, heat resistance, oil/water separation and biocompatibility. Ceramic coating parts for your vehicle also can improve the quality of the part i.e., ceramic coated pistons can assist higher fuel burning efficiency and reduced carbon accumulation, which in turn makes detonation more effective.

Powder Coating Flame spray Powder coating

What is flame spray used for?

Flame spray powder coating is a way to bring powder coating right to your shop or for us to powder coat oversized items i.e., Flag poles, balconies, fences, gates. The process involves preheating the part with the flame gun then spraying powder through the gun and baking it with the flame. Once it cools off, it’s done. Flame spraying powder has an industrial texture finish.