Diamondyze

The diamondyze advantage

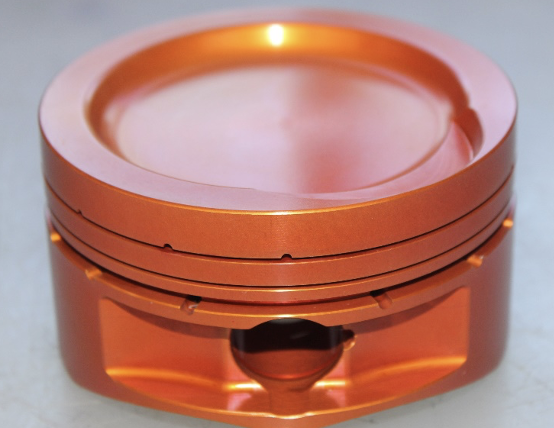

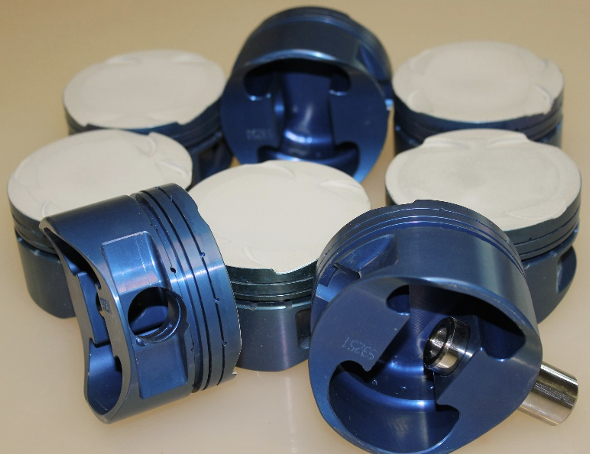

DiamonDyze is a breakthrough in colored and hard anodizing. The advanced ceramic formulation provides the applicator with the ability to color anodize parts AND impart extreme wear, thermal, chemical and corrosion resistance in one simple step.

Colored anodizing has several advantages compared to hard anodizing. It uses less hazardous materials, uses less energy and provides a smoother, less porous surface with good chemical and corrosion resistance. However, until now the only way to have extreme wear resistance was to turn to hard anodizing. Hard anodizing does create a very hard and durable surface but at the expense of the qualities that make colored anodizing so popular. Now DiamonDyze combines the best features of both.

DiamonDyze is simply added at the step where color would normally be imparted to a part undergoing the anodizing process. DiamonDyze replaces standard colored dyes in the process line. That is it. The result is a part that can be produced in any standard color available, including shades made by mixing the colors. DiamonDyze then increases the chemical and corrosion protection AND adds extreme wear resistance as well as increased thermal resistance.

DiamonDyze has proven to be so durable it has worn the teeth off files.

DiamonDyze can be applied to almost any aluminum part that normally can be anodized. This would include pistons, Aluminum Cylinder heads, Aluminum Rocker Arms, Intake Manifolds, Turbo Intake Housings, Shock Absorbers, Trailing Arms, and Aluminum Cylinder Sleeves to name just a few. This last item is extremely important as until now the traditional hardening process for aluminum cylinder sleeves/bores has been extremely expensive and is available at only a few locations.

Now any DiamonDyze licensed shop can provide this service.

All licensed applicators will receive training at their shop at this time, to assure that the process is properly understood and that the proper procedures are followed. While adding an anodizing line to a business capability will require an investment in the needed equipment, the cost including training will be comparable to the cost of installing the equipment needed to finish parts with metallic ceramic coatings. The return on the investment will be well worth the effort.

Existing Anodizing Shops, Machine Shops, Coating Applicators and Manufacturers will all benefit from this New and Advanced Technology.

Creates a hard highly wear resistant surface

Self lubricating capabilities

High corrosion and chemical resistance

Excellent ceramic thermal barrier

Excellent colour retention

Available in any brilliant anodized colour

Retains exact original part size

Superior in function and performance compared to any hard anodize coating

Links: Product Finishing Magazine Article: https://www.pfonline.com/articles/diamondyze-in-the-rough

Contains videos, testimonials and data tests: https://techlinecoatings.com/diamondyze/